- Home

- /

- PowerWash Industry

- /

- Fire Suppression Fusible Link Cleaning

Subscribe To Our Newsletter

Stay in the know on the latest products, deals, events, tips & tricks.

Social Media

Fire Suppression Fusible Link Cleaning

Link Cleaning by David Burrows, Getz Fire Equipment

Most of us have learned the hard way that fire suppression system fusible link detectors will not take much abuse. All fuse link detection lines are under constant tension, relieving the tension activates the control assembly to discharge the system. No one wants to hear that distinctive pop of a fuse link letting go. These tips will help you get the links clean without releasing the system.

The chemicals used to clean the metal surfaces in an exhaust system are highly caustic and corrosive to the alloys used to make fuse links, and may cause the links to separate. These chemicals should not be sprayed directly on the links. Over-spray is going to happen, do not let the chemical sit and soak on the links; use low pressure to rinse the chemical as soon as possible.

Do not spray high pressure directly at the fuse links. Do not allow the link to spin in the bracket when sprayed with the wand.

Remove grease build-up by hand when necessary, but be very careful when handling the cable, link, and detector. Before cleaning, check the links and cable for wear or fraying at the s-hooks, brackets, crimp connections, and conduit connections. If the cable looks worn in any spot the whole line could let go. If you see signs of worn parts, it may be best not to touch the links and let the business owner know why you are not cleaning them.

All fire equipment companies are required to replace the fuse links annually at a minimum. Links weaken over time during the normal operation of heating and cooling. The date of the replacement is to be noted on the system inspection tag. Check the tag to make sure the links are current; if not, use additional caution when working with the detection line.

Reasonable care should always be taken not to pull, bend, or move the fuse link brackets and conduit from the original position. Loose detection line can allow the cable to lose tension when moved.

This article appeared in the Spring 2002 IKECA Journal.

Share This Post

More To Explore

Soft Wash Additive That Smells Amazing? Meet Fresh Wash

Freshen Up Every Wash Soft washing is all about precision, power, and presentation — and nothing completes a job like ...

Mastering the Art of Pressure Washing: Key Insights on Surface Cleaners

For professionals in the pressure washing industry, a surface cleaner is an indispensable tool, particularly for those who specialize in ...

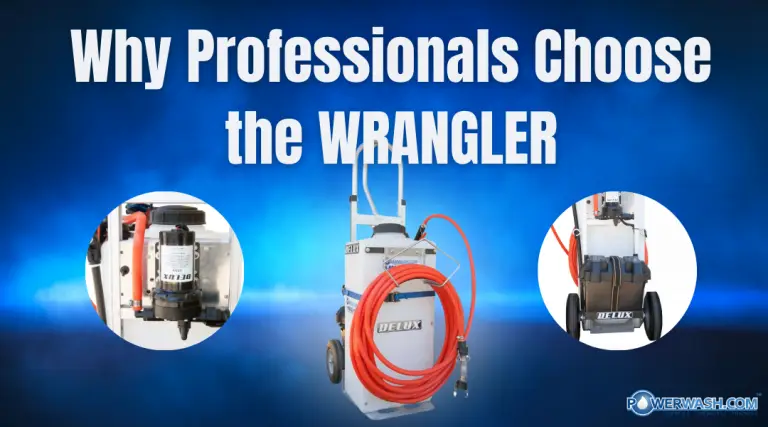

The Wrangler™ Chemical Sprayer: The Ultimate Tool for Professional Cleaning Applications

For commercial cleaners and pressure washing professionals, efficient chemical application is key to achieving the best results. The Wrangler™ Chemical ...

Professional-Grade Soft Washing with the PowerWash.com Maverick 12V Soft Wash System

Soft washing is an advanced cleaning method that utilizes low-pressure water combined with biodegradable cleaning agents to effectively remove organic ...